Industry is deemed a hard-to-abate sector due to its extensive, heterogeneous array of processes; GHG intensity; trade exposure; cost sensitivity; and long-lived facilities. While pathways for net-zero electric grids are being studied extensively, substantially less attention has been paid to industrial decarbonization. Yet, according to the IPCC, carbon dioxide (CO2) emissions from the industrial sector must decline 65-90% by 2050 to limit global warming to 1.5°C.

Industry is hard to decarbonize

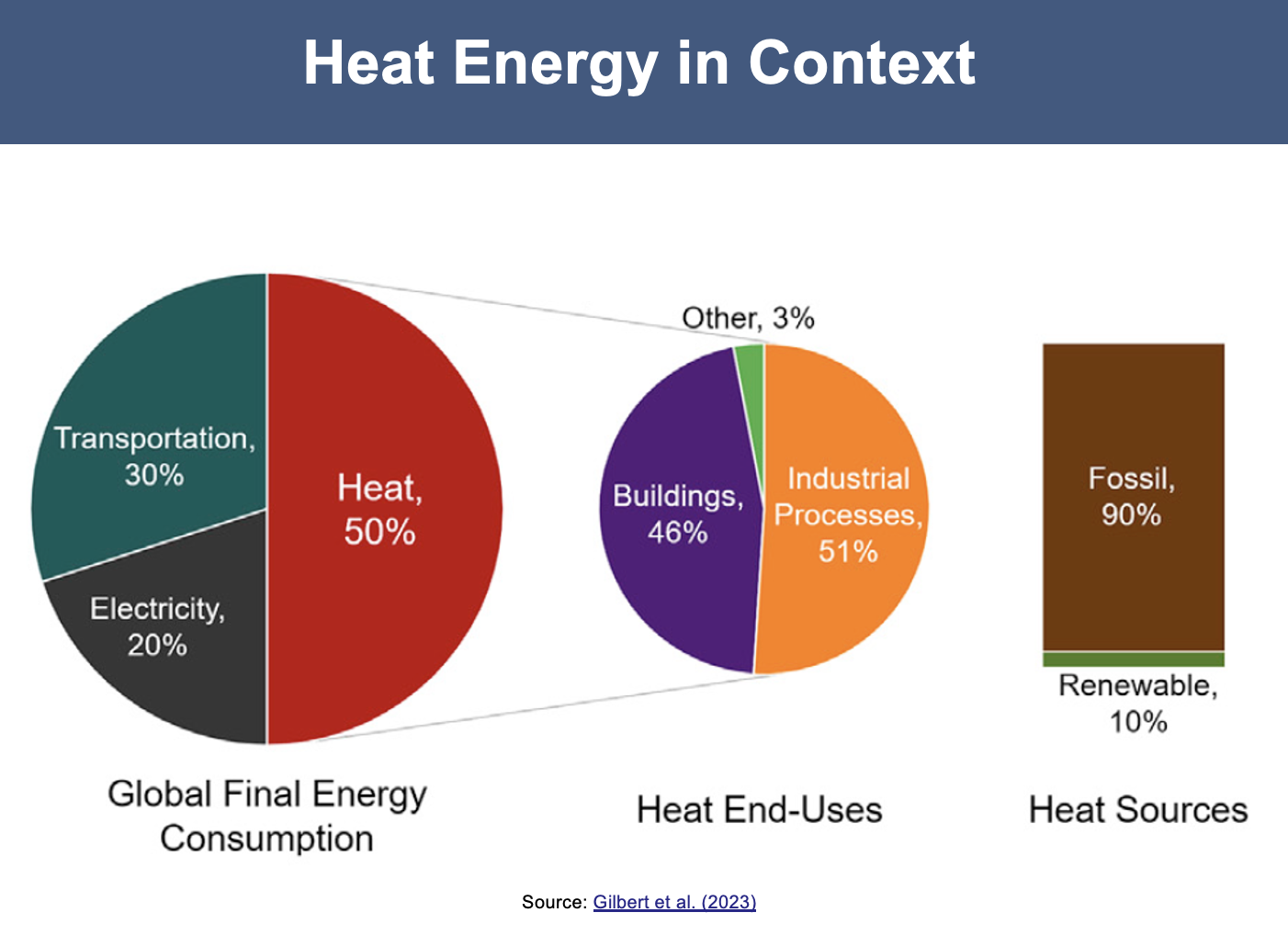

Half of global primary energy is for thermal uses, and industrial processes consume 51% of that heat (for process heating, process reactions, process evaporation, concentration, and drying). Nearly all heat is provided by hydrocarbon combustion.

Nuclear technology holds vast and untapped potential to decarbonize the industrial sector, which accounts for a third of U.S. energy-related CO2 emissions. Low-carbon, high-reliability nuclear technology is a broadly applicable pathway across an extensive array of industrial processes. Advancements in nuclear technology, regulatory modernization, public incentivization, and private investment are starting to answer societal demands for deep decarbonization. With the potential to be cost-competitive with fossil fuel combustion, and deployable without geographical limitations, nuclear technology can help secure industrial sector jobs, reduce carbon emissions, and decrease local pollution. The growing unreliability of the U.S. electric grid is another impetus to consider nuclear.

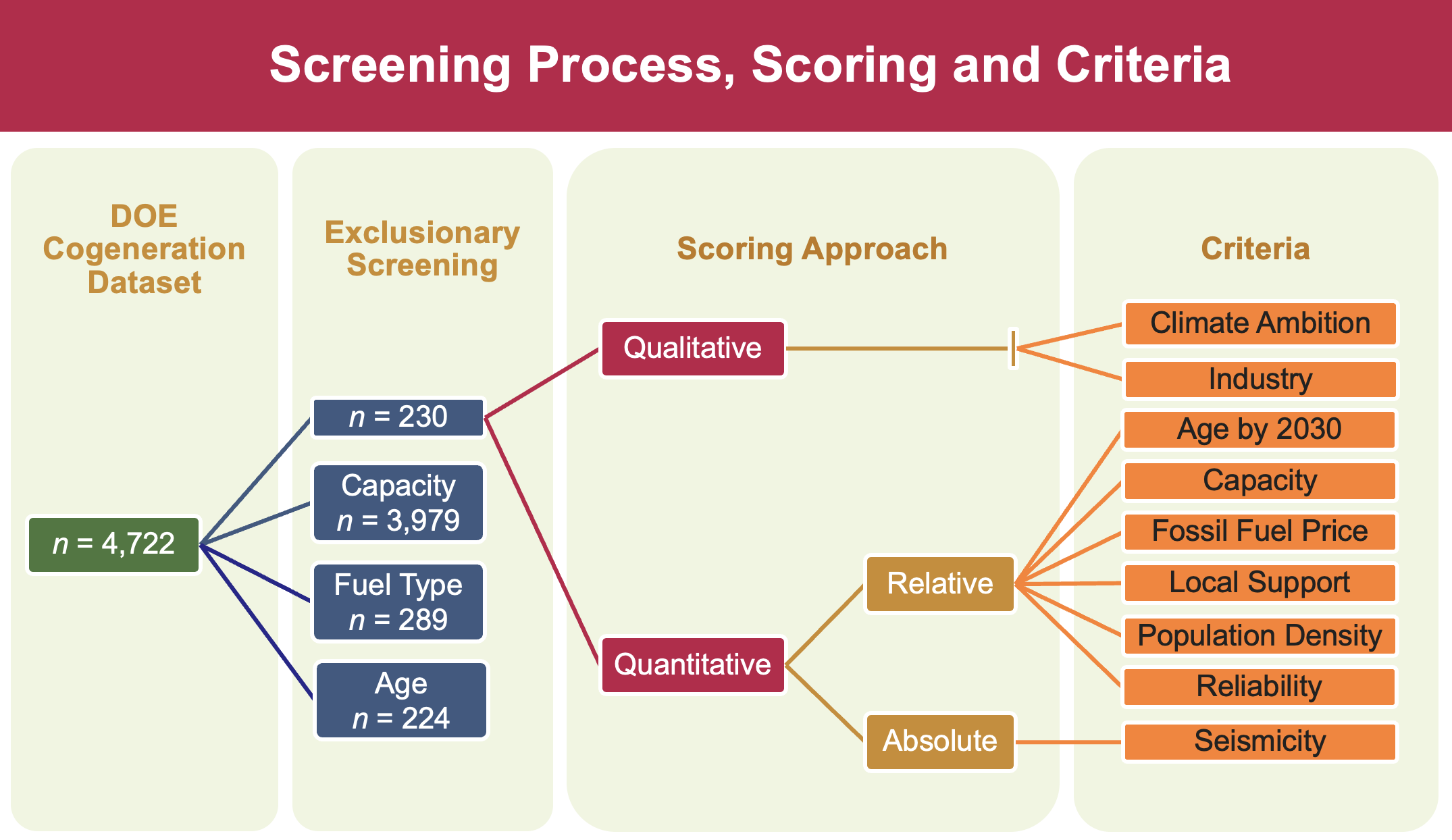

This project evaluated U.S. industrial fossil fuel assets to identify the facilities most suitable for early adoption of this emergent technology. Internal considerations in developing a priority list of nuclear repowering opportunities were: facility generation capacity, fuel type, industry, temperature requirement, reliability need, and age. External factors considered were: local support for new nuclear plants, maximum regional population density, seismicity, fossil fuel prices, and climate commitments made by facility owners. Criteria scores were assigned to each facility by drawing upon existing literature, combining multiple datasets, and using geospatial analysis.

Legacy REGULATORY Limits

Legacy U.S. regulations, promulgated for conventional large reactors, have prohibited nuclear plants at a majority of industrial facilities. Existing rules require that reactor licensees establish an exclusion area, a low population zone, and determine that the population density within a 20-mile radius may not exceed 500 persons per square mile. Based on this siting criterion, the majority of U.S. cogeneration plant capacity is not eligible for nuclear replacement: 60% coal, 73% fuel oil and diesel, and 60% old gas (install dates on or before 2000).

REGULATORY Modernization

The Nuclear Regulatory Commission recognizes that advanced nuclear designs build upon half a century of engineering progress and incorporate different fuel forms, coolants, and barriers limiting the potential release of radioactive material beyond the site boundary. These inherent safety features and a transition towards a regulatory approach that is performance-based, technology-inclusive, risk-informed, and consequence-oriented is helping to unlock the industrial application of nuclear energy.

BY TEMPERATURE

In the U.S., heat sources below 550°C can satisfy 80% of industrial process requirements, and all cogeneration heat requirements

BY INDUSTRY

Approximately 78% of U.S. industrial heat energy was used in the chemicals, petroleum refining, pulp and paper, and food and beverage subsectors.

Conventional nuclear reactors can provide 275-325°C heat, high enough for desalination and district heating (~150°C). However, advanced nuclear designs currently under development will be able to generate 500-800°C temperatures. Petroleum refining, chemical manufacturing, nitrogenous fertilizer production, and ethyl alcohol production plants have the highest economic potential to adopt onsite nuclear generation. As a large energy consumer with a heat temperature range that matches the output of advanced nuclear reactors, the chemical industry is a prime target. In its energy policy statement, the American Chemical Society, the largest professional society for chemists, identified the need for a stable and sustainable supply of energy from low-carbon technologies such as nuclear.

In late 2022, U.S. industrial leader Dow Inc. partnered with Rockville, Maryland-based advanced nuclear developer X-energy to demonstrate a high-temperature gas reactor (HTGR) for industrial decarbonization. The Dow X-energy nuclear cogeneration project, at the Seadrift facility in Texas, is part of the Department of Energy Advanced Reactor Demonstration Program (ARDP), which seeks to de-risk advanced reactors through cost-shared partnerships with private industry. Dow’s Seadrift is the company’s second largest facility in Texas, spanning 4,700 acres and employing more than 1,200 people in Calhoun County.

A key driver towards nuclear cogeneration is industrial facility owner interest in deep decarbonization. This project considered prospective customers’ stated public climate commitments as a proxy marker for organizational mobilization. Figure 3 is a scatter plot of facility owners’ public greenhouse gas emission reduction goals by year. Companies with a “30% reduction by 2030” appear at the 30% level over the year 2030. Companies inside the green triangle have nearer-term and higher ambition compared to those in the red triangle.

Mapped here are the top 35 industrial cogeneration facilities most amenable for nuclear repowering, each plant indicated by a circle that is proportionately sized to generation capacity. The markers are color coded by industrial sector, and are accompanied by ID keys.

Contact the author for further collaboration.